«Zavod Preform» offers high-quality preforms for blowing plastic bottles. We minimize the PET bottle rejects to ensure that our customers receive only high-quality products at an affordable price.

Let's consider a number of situations when the material for further production of packaging gets defects and becomes unsuitable for use.

Contents

Defects of PET bottles

In production PET preforms high-tech polymer is used — polyethylene terephthalate. Plastic is also used in the production of packaging and medical products. Material:

- ✅ light,

- ✅ transparent,

- ✅ safe,

- ✅ durable.

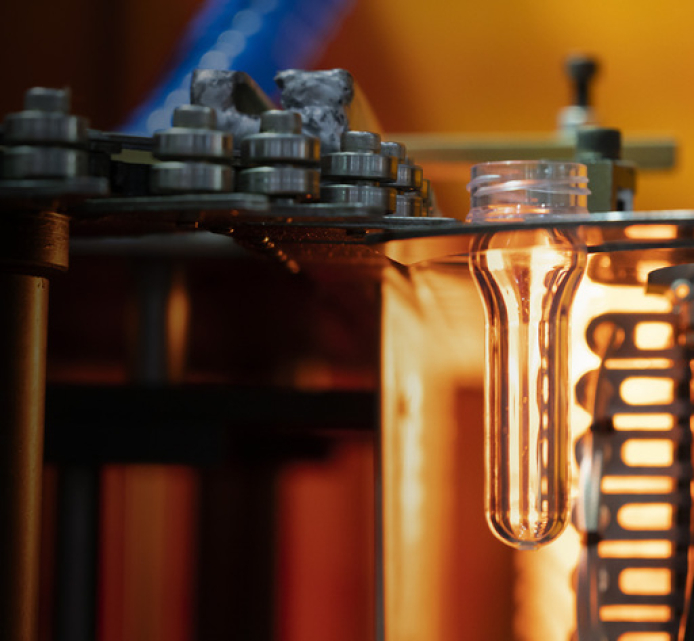

A container for storing food and non-food liquids is created on the basis of polyethylene terephthalate. The process of creating PET bottles includes two stages: preform production, plastic container blowing. The quality of production affects the result of production.

If the blanks were produced with violations, the disadvantages of plastic containers may be as follows:

- ✅ deformation of the neck;

- ✅ different wall thicknesses;

- ✅ bottom deformation;

- ✅ air pocket formation;

- ✅ pollution of preforms;

- ✅ cracking walls.

Such preform defects occur for a number of reasons. If the blowing technology is violated, the walls of the bottle can be deformed, holes are formed on them, and cracking appears. This entails the impossibility of using ready-made containers for storing food and non-food products. Otherwise, liquid leakage will be observed.

Sometimes in the process of blowing the bottle does not stretch enough. In order to cope with this problem, the purge pressure increases, and the purge time decreases. The problem of uneven wall thickness is to adjust the pressure before blowing, to ensure uniform heating of the billet. The disadvantage of an uneven base is also solved by adjusting the temperature of the mold and the pressure of the blow.

The deformation of the container can also be called a common type of damage. The bottle is asymmetrical. It is not suitable for storing liquids. To solve the production problem, to prevent the appearance of defects, it is necessary to maintain a constant pressure before blowing out the container.

Sometimes air pockets may appear on the surface of plastic walls. Presence of bubbles — the result of poorly regulated blowing pressure, uneven heating.

If during the production process the preforms are contaminated with foreign particles, such ingots are considered defective. They cannot be used for further production of containers. Contamination can occur during the process of transportation and storage of ingots.

Defects of sprues are caused by incorrect shutter design or shutter temperature. The sprue can be elongated, which manifests itself as a molten protrusion on the workpiece.

Other defects also include:

- ✅ turbidity of preforms;

- ✅ yellowing of walls or color change;

- ✅ surface defects;

- ✅ deep dividing lines;

- ✅ spots of crystallization in the neck region;

- ✅ splits, needle holes, colored veins. >

Problem solving

"Zavod Preform" strictly monitors the quality of production. We take the necessary measures to prevent shortages. We have trained staff. The masters know all the intricacies of the correct use of the equipment. They strictly monitor quality. This minimizes the possible risks of producing products with defects.

We regularly monitor production parameters. We monitor pressure, speed, manufacturing temperature (heating, cooling). We regularly carry out inspections, identify shortcomings and potential problems. Timely control, attention to detail allows us to prevent situations that lead to the production of defective products.